Internship Projects

Summer 2021

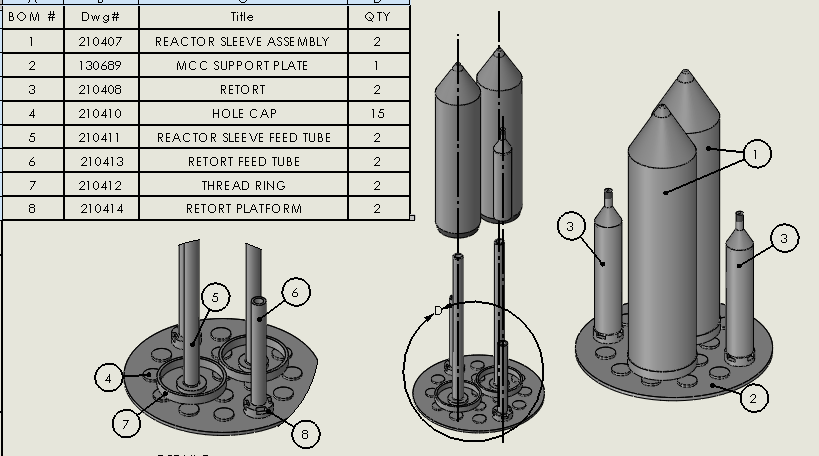

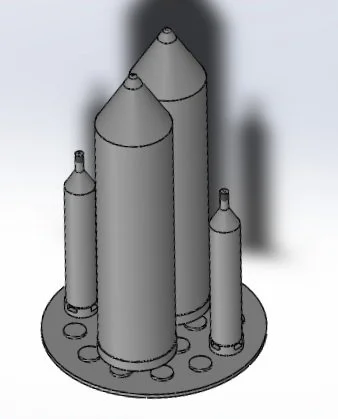

A company sent us these four reactor tubes. I was tasked with designing fixtures to hold the tubes upright, cover the threading, and ensure proper gas flow.

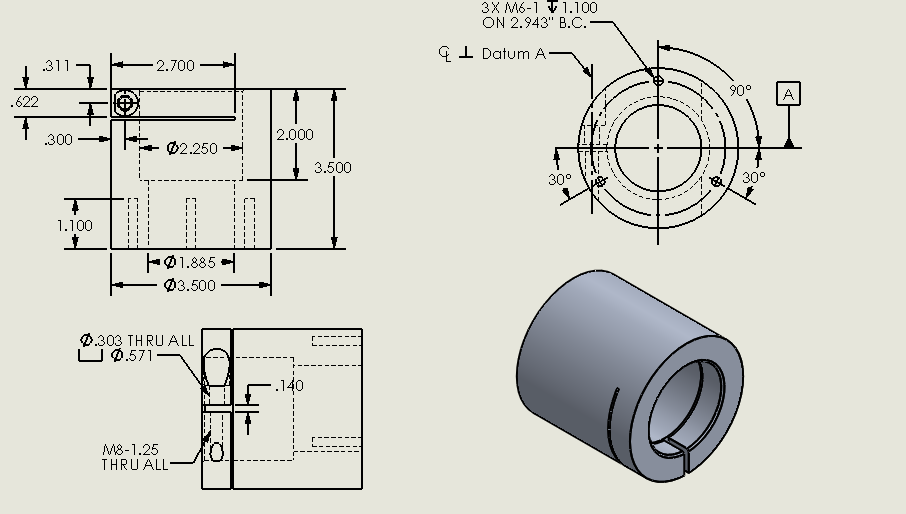

I had to create models of the reactor tubes from scratch, using customer drawings as well as hand measurements.

All of the parts were designed for CNC Machining, made from graphite. I then assembled everything into the furnace by hand, ensuring that all parts would fit together properly.

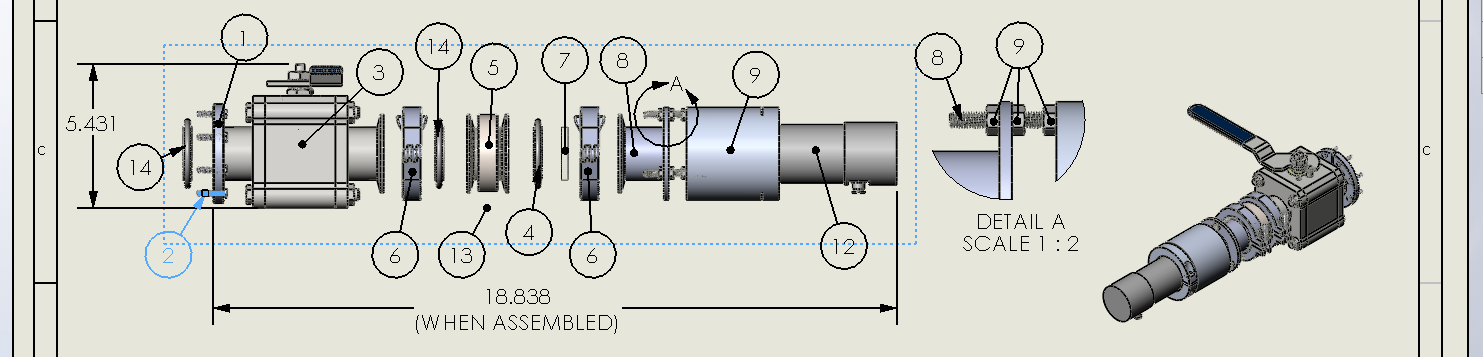

For this project, I was tasked with redesigning the pyrometer we were currently using to be able to hold two different sized pyrometers.

I was able to achieve this by moving from stainless steel to aluminum. The aluminum part allowed for a little more give, allowing it to fit a range of sizes of pyrometer.

In order to measure the temperature inside our furnaces, we have these sight-port assemblies that allow a pyrometer to view inside the furnace. I was tasked with creating CAD models of each part, as well as creating the assembly and making a BOM (bill of materials).